3D CAD & Solid Modelling

CAD technology.

Computer Aided Drafting or Design offers several methods of representing the design model:2D - Lines and text, similar to conventional drawing board.

3D - Vertices (corners or points in space), edges, surfaces in x, y and z.

Solid modelling - Solid geometry, fully defined three dimensional solid shapes, with free-form curved faces, material and mass properties.

Different methods suit different design circumstances. This section will introduce you to the most significant and expanding technology, Solid Modelling.

The graph below gives a very crude indication of the productivity of companies developing CAD software, through time.

All of the acronyms below may be used in the context of mechanical computer aided engineering:

CAD - Computer Aided Design/Drafting

MCAD - Mechanical Computer Aided Design

CAE - Computer Aided Engineering

Part modelling

You can create 3D solid part models of your designs, such as this connecting rod. The dimensions that define the model are related to each other and can be changed and controlled. So, if you change one dimension, others will change with it. Software that allows this is refereed to as parametric. For example, change the centre distance of the bores of this connecting rod and the whole model will stretch out.

You can create 3D solid part models of your designs, such as this connecting rod. The dimensions that define the model are related to each other and can be changed and controlled. So, if you change one dimension, others will change with it. Software that allows this is refereed to as parametric. For example, change the centre distance of the bores of this connecting rod and the whole model will stretch out.You can also assign material properties, analyse mass properties, control the colour and texture of the appearance, create photo realistic images with lighting, shadows and perspective.

Orthographic drawing

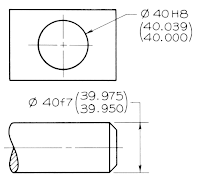

From the 3D model you can also create a detailed orthographic projection drawing. You can easily modify the design. Because the solid part file and the drawing file are connected, or associated with each other, a change in one will appear in the other. Change a dimension in the solid part and the same dimension will be updated in the drawing.

From the 3D model you can also create a detailed orthographic projection drawing. You can easily modify the design. Because the solid part file and the drawing file are connected, or associated with each other, a change in one will appear in the other. Change a dimension in the solid part and the same dimension will be updated in the drawing.Most market leading solid modelling software offers this associativity and is usually referred to as 3D parametric associative solid modelling software.

Assembly modelling

Solid model parts can be assembled. The assembly files can enjoy the same associativity as do part and drawing files. The connecting rod above has been assembled here with a crank shaft and a piston.

Analysing your design

Having created a 3D solid model of a component, the geometry can then be used to predict how it may behave in real life.

For example:

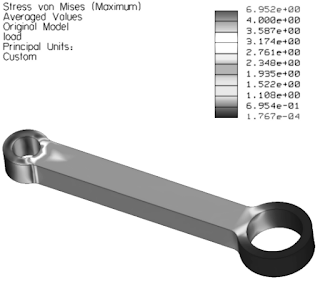

To predict how high the stresses may be and how much the connecting rod may deflect under load, CAD software can be used to apply loads and supports and then analyse the structural behaviour of the model.

As the design engineer, you can use the analysis results to help you decide whether the design is acceptable or requires modification. You may decide for the connecting rod , that the stresses are too high around the small end and modify the design accordingly. You run the analysis again, continuing the process until the predicted stress values are acceptable.

Visualise your design

As time passes more and more 3D CAD software packages allow you to create high quality photorealistic images of your designs. By setting up an environment, with surrounding walls, a floor and a ceiling, lights, surface textures, etc. you can capture impressive images that cast shadows and reflections, giving a much more realistic impression of what your design may look like once manufactured. These facilities provide very powerful tools for developing, communicating and selling design ideas.

Most consumer product designs are modelled using 3D CAD software and then photo rendered as part of the product development process. Most public building designs now are also treated in the same way.